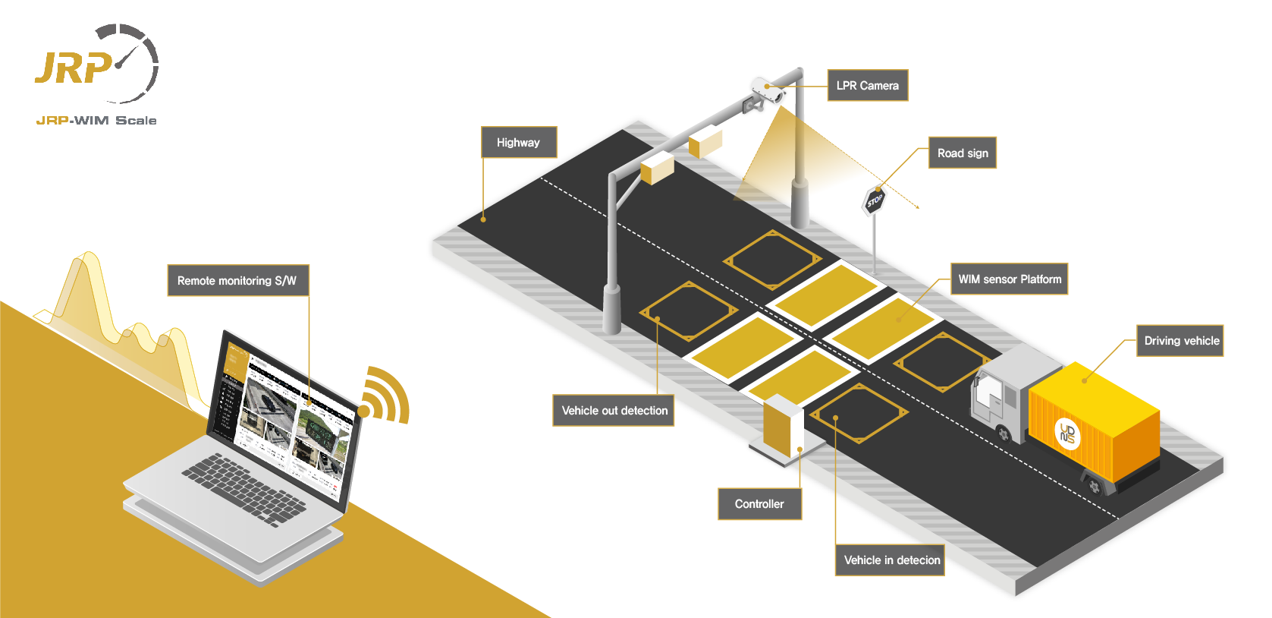

Weigh In Motion

Wide field of Feature

ㆍHigh Accuracy and moderate cost

GVW ±5~7%, AOW ±10~15%

COST323: A5-B7 class, OIML R134: F class

ㆍUser customized solution

Company registration, Vehicle management

Automatic payload calculation

Overload preselection and historical view

Cycle number by vehicles, Weighing by materials

ㆍVerified performance in actual driving characteristics

Wide range of vehicle speed: 0~200km/h, Measurable in traffic jam or acceleration condition

Lane departure driving detection and Estimated weight display for preselection

Proven reference

ㆍLaw enforcement of overload vehicles(preselection)

ㆍSpecial bridges safety management by entering vehicles weighing

ㆍSmart tolling ETCS for trucks

ㆍTraffic information management and statistics

ㆍConstruction progress monitoring

ㆍWeighing by materials of concrete plants

ㆍIn / Out Cargo weight measurement at plant

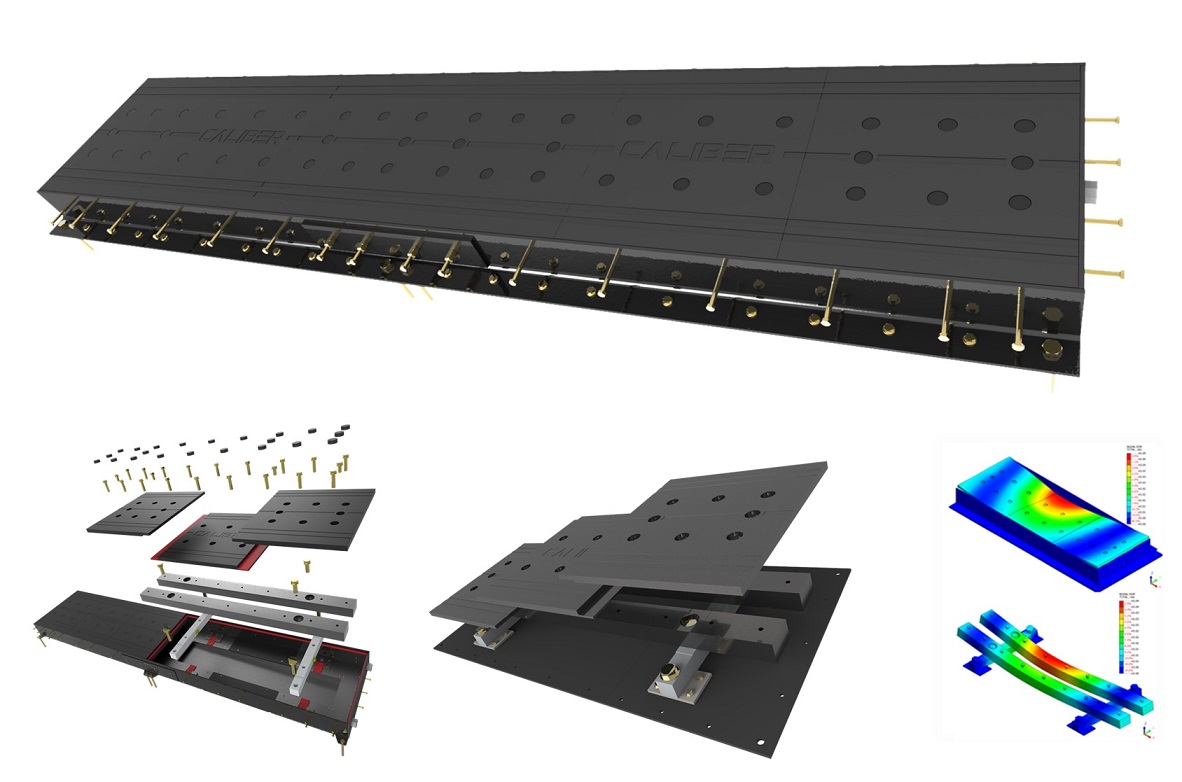

Feature #1

ㆍFully prefabricated system

ㆍHigh accuracy, durability

ㆍExcellent long term stability

ㆍWide speed range (0~200km/h)

ㆍRobust, Waterproofing package

ㆍ3-splited bending plates

ㆍLong term life cycle

Feature #2

ㆍAvailable to all pavements

ㆍDetection of wheel types and positions

ㆍPlatform leveling device, easy and economical maintenance

ㆍSensor replaceable

ㆍApplied proper torque assemble

ㆍThermometer (RTD) embedded

Feature #1

ㆍController for JRP-WIM installing inside of outdoor enclosure

ㆍVehicle detection, Dynamic weight measuring function

ㆍAutomatic vehicle classification

ㆍAnalysis of vehicle information(wheel track, wheelbase, axle type)

ㆍLane departure driving detection

ㆍSignal processing algorithm for weight accuracy

ㆍCompensation function for temperature and velocity

Feature #2

ㆍOutstanding expandability(modularized)

ㆍKC, CE certified

ㆍCable and ground noise filtering function

ㆍNoise filtering using vehicle natural frequency

ㆍFast computing speed and high stability and durability

ㆍLow power consumption, AVR(Automation Voltage Regulator) embedded

ㆍAVI(Automatic Vehicle Identification) VMS(Variable Message Sign) System linkable

Monitoring information

ㆍSystem operation monitoring

Vehicle detection info, Operation Error

Connected device status, Communication status

User authorization management, History log

ㆍVehicle measurement information

Real-time video, Individual detail views

Overload vehicle data management

SMS Alarm for pre-selection & operation

ㆍStatistical analysis

Traffic volume, Traffic patterns

Overload vehicle data &driving pattern

Statistical analysis, Result report

Measuring data

ㆍSite code, driving direction, Lane

ㆍVehicle entry and exit date / time

ㆍVehicle front/side/roof view image

ㆍVehicle license plate no.

ㆍWeight(gross, axle, group, wheel, Payload)

ㆍVehicle company, Cargo type

ㆍSpeed, acceleration

ㆍWheel ground position

ㆍVehicle classification result

ㆍAxle No, Type of axle, Wheel type

ㆍVehicle length, Overhang, Temperature

ㆍOperation logs, Statistical Analysis Data

Criteria for the site #1

ㆍInstallation area: W3.4xD7.6m

ㆍFlatness < IRI 2.0

ㆍSlope < 2%

ㆍRadius of curvature > 1km

Criteria for the site #2

ㆍConcrete pavement depth> 250mm

(Replacement packaging method is used in other cases)

ㆍPower supply (AC 220V)

ㆍInternet connection area (> 10Mbps)

Case study #1

The JRP-WIM system, which is installed in Yeosu National Industrial Complex, connects Yeosu and Gwangyang to Lee Soon-Shin Bridge. It is used as a vehicle weight information management system, an overload prevention and pre-selection system for heavy vehicles. Provides effective overload prevention system by sending suspicious vehicle information to enforcement police.

Case study #2

The JRP-WIM system installed in the Songdo 4 bridge connecting Incheon Songdo New Port and Namdong Industrial Complex is used for traffic statistics purposes to evaluate the performance impact of the bridge due to cumulative fatigue load due to frequent passage of large trucks. Provides management information for maintenance.

Case study #3

The JRP-WIM system installed in the YNCC of Yeosu National Industrial Complex was applied to the vehicle weight information management system. It is used to measure irregularity of the amount of construction waste (aggregate, soil, etc.) generated in the construction site. Provides real-time on-site monitoring and vehicle operation history management.

Case study #4

The JRP-WIM system installed in the approach road of the Woorim Concrete Ind. Co., Ltd. is applied to the factory material weight information management system(the exact stock amount, source and history of the material-gravel, sand, slag, fly ash etc). It provides to monitor the exact loading weight by source at remote warehouse management office, and provide decision making materials to calculate the exact order quantity according to the shipment quantity.