Truck weight&location monitoring

Wide field of Feature

ㆍHigh accuracy performance

3 to 5% accuracy error rate

Not only the gross weight of the vehicle but also real time confirmation

weight / location / video information provided

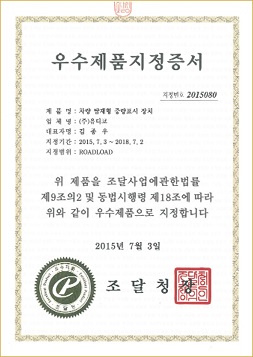

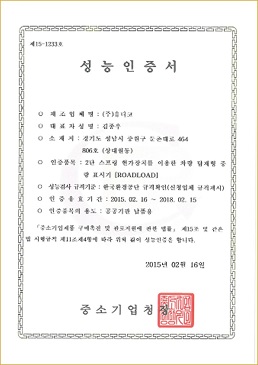

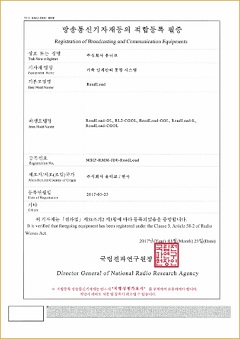

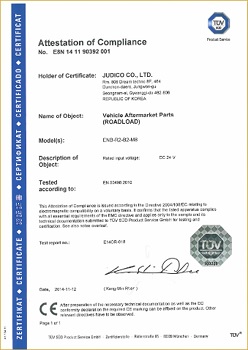

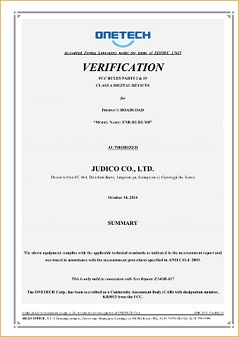

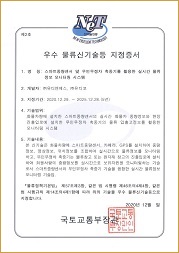

Acquired government procurement product certification

ㆍWide Application

Applicable to various sensors(MEMS tilt sensor, pressure sensor and load cell)

Automotive standard communication area network (CAN) communication

ㆍRugged Durability

Achieve performance at the automotive industry level

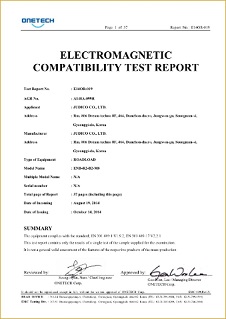

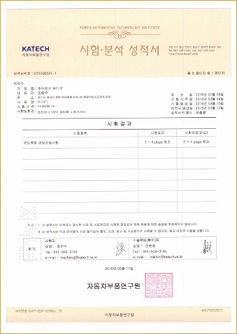

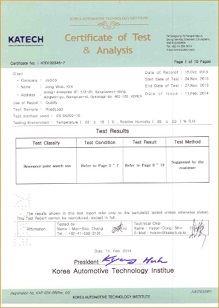

Certified test of KATEC (Korea Automotive Parts Research Institute, http://www.katech.re.kr) Test

Easy mounting installation without disassembly, welding, drilling, etc.

ㆍMonitoring and control solution

Smartphone App connectable with Bluetooth

3G / 4G network support to link with the central monitoring platform

Weight of vehicle / GPS location, Status of operation, Location area, time and weight of loading/Unloading, Cycle counts

Checking overloading, unauthorized dumping, permitted zone departure

Proven reference

ㆍSelf weighing of freight vehicles

ㆍManaging weight of construction site

ㆍChecking proper treatment of environmental substances

ㆍDanger and Hazardous Substance Disaster Control and Transportation Control

ㆍApplicable vehicle

Axle: 2, 3, 4, 5 axle tractor

Type: Dump, Cargo, Wingbody, Timber, Woodchip, Tank lorry, Roadside cleaning car etc

Structure: Leaf spring suspension only

Advanced sensor technology

ㆍHigh-precision and CAN communication

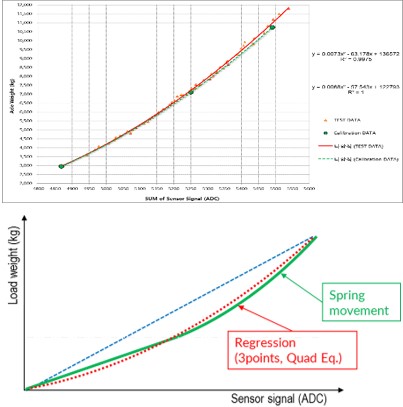

High-precision angle measurement with ± 0.5% F.S accuracy

Applied to automotive standard CAN communication

ㆍWaterproof IP67 grade

Small size of W38 × D60 × H20mm

the highest waterproof dustproof grade IP67

high strength polycarbonate (PC) material applied

ㆍEasy installation

Simple attachment and installation without welding or drilling

Novel idea

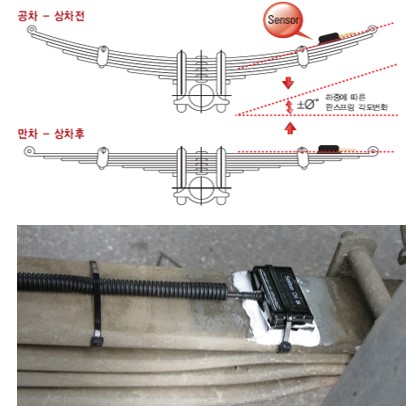

ㆍSmart conversion

Installation of MEMs tilt sensor on leaf spring suspension of commercial vehicle

By measuring the angle change of the leaf spring according to the loading load, it can be converted into weight

The weight can be measured even on inclined uneven terrain

ㆍSpecialized algorithm by sensor and axle type

Convert to congratulation using special algorithm according to applied sensor type and type of shaft(single, tandem)

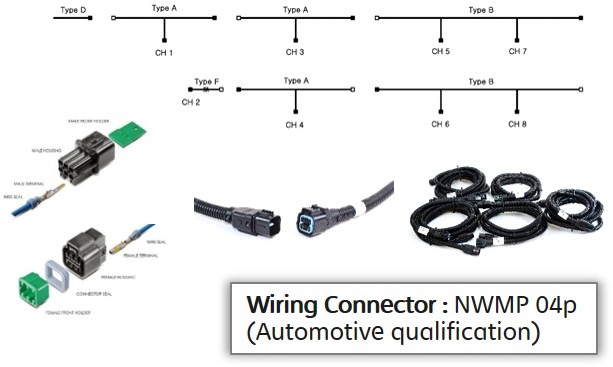

High reliability

ㆍExcellent weather resistance

mall multi-pole waterproof connector with special waterproof LOCK mechanism

Special double locking structure, independent seal structure, BRIDGE structure, CLICK LOCK method

ㆍCustomized cable combinations

Customized cable combinations for each vehicle structure and sensor type

Easy Linking Solution

ㆍConnection to smart phone

Linking smartphone app, checking weight and setting via Bluetooth communication

ㆍOptional service with external device

Connectable external device using serial communication

Communication with web platform which can provide gross weight, axle weight, payload, location data in realtime.

ㆍCustom housing

Custom housings based on ordering agency and requested solution

Feature #1

ㆍReal time weighing with smartphone when loading

Link with smartphone app via Bluetooth communication

It provide weighing information of gross, axle, payload in real-time.

ㆍEfficient overload prevention and safe driving

Driver adjusts shaft distribution to avoid eccentricity when loading

The driver can departure after checking the weight in real-time without any additional weighing procedure.

Feature #2

ㆍEasy setting of truck structure

Free setting of the number of axles of the vehicle and the suspension structure of each axles

Variable setting management such as fit algorithm and conversion factor for each sensor

ㆍTested by mobile phone models

ompleted testing of 34 mobile phones (Android version 4.1.2 or higher required)

Available after downloading from Google Play Store

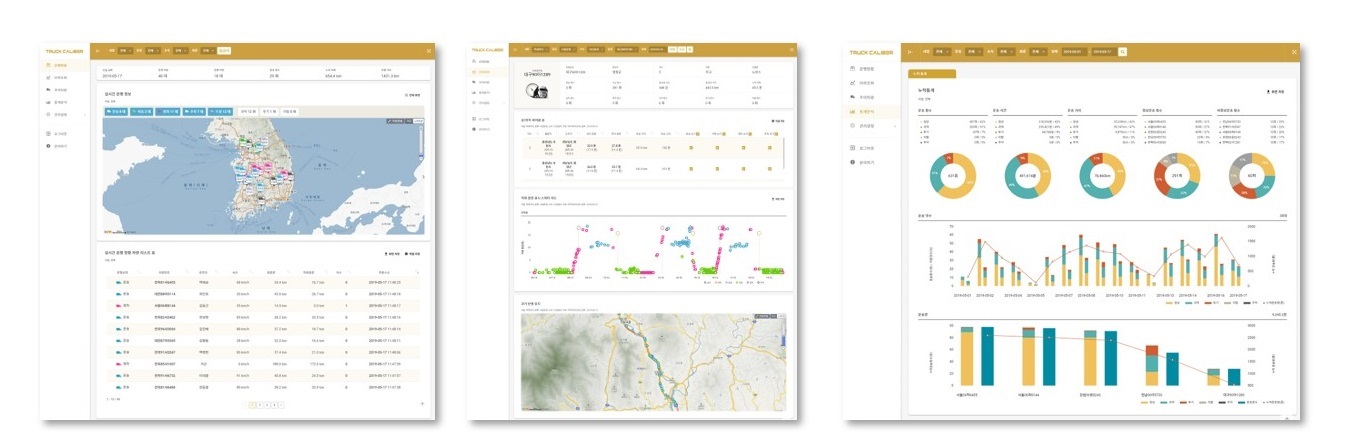

Real-time monitoring

ㆍReal-time location and weight monitoring web platform

Real-time location/weight check at any time by accessing the web platform

Provides real-time location, speed, gross/axle weight, payload, and loading information

Historical driving route, loading/unloading cycle, payload graph by time

ㆍAI-based status determination algorithm

Automatic identification of trucking, moving, stopping and parking of truck operation status

Automatic identification of overload, abandon and out of zone

Automatic preparation of electronic shipment invoice by discriminating loading weight, place and time

Custom user interface

ㆍVehicle Status

Operation status (transportation, movement, stop, parking, interruption) and caution operation (normal, overload, dumping, departure)

ㆍHistorical view

Vehicle’s transportation cycle, loading weight change graph, driving route on map

ㆍCaution vehicles

Display the number and the time of transportation of caution vehicles

ㆍStatistical analysis

Provides cumulative statistics of number of times, time and distance, and displays normal/abnormal transportation statistics graph

ㆍManagement setting

Project, vehicle management and user authority setting

Simple installation

ㆍSimple installation of the sensor

Simple attachment on the leaf spring after scrapping and silicon insulation

Installation without welding or drilling

Customized cable combinations for each vehicle structure and sensor type

ㆍInstallation work by 2 experts

Professional installation team can work quickly within just 1 hour

Adjusting the installation schedule according to the driving route so as not to interfere with the transportation business

Easy calibration

ㆍEasy calibration work with smartphone App

ㆍInput empty weight

After measuring each axle weight using the reference weighing equipment (Truck scale or Potable wheel scale) in the empty state, input the empty weight value in the smartphone App

ㆍInput full weight

After measuring each axle weight using the reference weighing equipment (Truck scale or Potable wheel scale) in the full state, input the full weight value in the smartphone App

Case study #1

"TruckCaliber", which is installed in the vehicle of private and transport company', provides the driver to the information of gross, axle and payload weight in real time with a smartphone app. The driver can maximize the loading weight in the safety range and prevent overload in advance. In addition, driver do not have to drive far distance by truck scale to check the overload weight, thus ensuring more efficient and safer driving operation.

Case study #2

In the case of a loading area that does not have a separate weighbridge, cargo vehicles equipped with TruckCaliber can self-check the exact amount of loading weight in real time without any weighing procedure. In addition, it provides managing axle weight by adjusting the loading point so that create a safe axle road during transport. And it contribute to prevent illegal arranging of overloads and resolve shipping charges dispute in advance.

Case study #3

The livestock manure Service Management System is used for Korean Ministry of Environment, which transparently manages entire processing for the discharge, collection and transportation from the livestock farming, to recycling factory. "TruckCaliber" is installed with sensors, on board unit, IR camera, GPS, modem, etc. and transmitted the operation data to the server. The office manager can monitor proper treatment of environmental substances, checking illegal dumping and permitted zone departure.

Case study #4

In the case of waste or dangerous environmental material collection and transportation vehicles, there are cases in which illegally dumping on the route to the treatment station or driving on an arbitrary route without permission to operate in order to save money. If there is accidents in water supply protection areas or downtown, it may lead to catastrophic disasters. "Truck Caliber" is installed in such collection and transport vehicles to prevent illegal dumping and to provide proper monitoring of freight weight and driving route, so that it helps to check the proper handling at the loading and unloading places as a smart invoice or waybill.